Casting thiab Extrusion Green Cov Tshuaj Txhaum Sib Raug Nyiaj Silicon Carbide Micropowder

Yam khoom:

1.We tsim RBSIC Micro hmoov xws li F240, F1200, W20, W14, # 90, # 150 thiab lwm yam.

2. Lawv muaj qhov zoo xws li fluidity zoo, purity zoo, nkoj cov nplej zoo, tsim nyog cov khoom faib loj thiab cov ntim ntawm cov khoom ntim siab, thiab lwm yam.

3. Peb RBSiC micro hmoov tau txais zoo los ntawm cov neeg siv khoom

Daim ntawv thov:

Uas siv rau hauv cov txheej txheem plam casting thiab txheej txheem txheej txheem ntawm RBSIC cov khoom lag luam, xws li Kiln Rooj Tog Cuam Tshuam thiab Cov Kev Txhawb Nqa, Cov Rollers, Cov cua txias rau cov kav dej, Cov hlawv qhov cub thiab cov ntsaws ntsaws ntsaws, Cov ntsaws ruaj ruaj thiab Vanes, Nozzles, Cantilevers Paddles, Kauv Nozzles, Precision Cheebtsam lwm yam.

Tshuaj lom neeg ntsiab lus

|

Qauv |

SiC |

Fe2O3 |

FC |

SiO2 |

PH |

Cov ntsiab lus dej |

|

F240 |

99.50% |

0.06% |

0.07% |

0.08% |

7 |

0.01% |

|

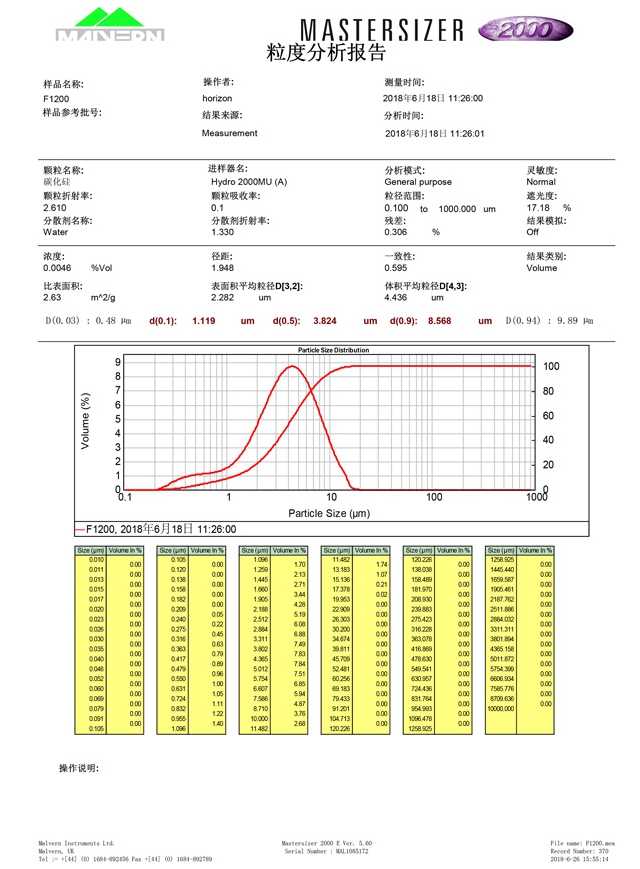

F1200 |

0.9935 |

0.0003 |

0.0009 |

0.001 |

7 |

0.0002 |

|

W14 |

99.40% |

0.02% |

0.08% |

0.10% |

700.00% |

2.00% |

|

W20 |

99.40% |

0.03% |

0.08% |

0.09% |

700.00% |

0.02% |

Packing: 25Kg / 50kg Lub Hnab yas lossis Customized raws li Cov Neeg Siv Khoom

Lub sij hawm xa tuaj: 1 * 20GP thawv yuav siv sijhawm li 7 txog 10 hnub

MOQ: 1Ton

Cov qauv: Yog tias cov neeg xav tau, Kev kuaj dawb thiab muaj nqi thauj khoom

Cov Txheej Txheem Ntau Lawm:

Cov tshuaj tiv thaiv-sib xyaw ua ke silicon carbide yog tsim los ntawm kev sib xyaw SiC hmoov nrog cov pa roj carbon thiab cov yas, ua qhov sib xyaw kom haum rau hauv cov duab yam xav tau, hlawv tawm ntawm cov yas, thiab tom qab ntawd ua rau cov khoom siv hluav taws xob nrog cov roj cua lossis yaj ua kua, uas cov tshuaj tiv thaiv nrog cov pa roj carbon los tsim ntxiv SiC.

Cov khoom uas ua rau xaiv cov khoom siv yog:

1. Ris taus hnav

2.Res tiv taus corrosion; cov khoom zam ntau ntau cov kua qaub thiab alkalis

3. Rho tawm ntawm kev oxidation

4.Abrasion tsis kam

5. zoo zoo poob siab kuj vim tsis thermal expansion coefficient thiab siab thermal conductivity

6.Cov khoom thaum qhov kub kub

7. zoo ntsuas kev ntawm cov khoom txawv

Kev Koom Tes Txheej Txheem rau cov neeg siv khoom tshiab

1.Txhais khoom siv nrog cov qhua lag luam los ntawm email thiab xov tooj paub zoo txog cov neeg siv khoom kev lag luam thiab qhov yuav tsum tau ua ntawm Silicon Carbide parameter.

2.Peb muab cov qhua tuaj yeem ua qhov zoo tshaj plaws thiab cov lus pom zoo ntawm cov qauv khoom.

3.Itsev muaj rau xa cov qauv lossis xa tawm hauv pob me me kom kuaj xyuas qhov zoo

4. Tom qab cov neeg siv khoom pov thawj, ua raws li qhov no raws li tus qauv thiab mus rau hauv ntau lawm, khaws qee qhov qauv kom ob tog tuaj yeem tshawb xyuas yav tom ntej.